In the pelleting world, there is a choice to be made between two operating principles of the pelleting process – flat die or ring die – each with its own set of merits. With its latest Twin Track innovation, CPM is pushing the boundary of capacity and efficiency for the latter principle to a whole new level.

Please reload the page

Do you want to read the whole article?

- Six editions per year

- Full access to all digital content

- The E-magazine Bioenergy international

- And more ...

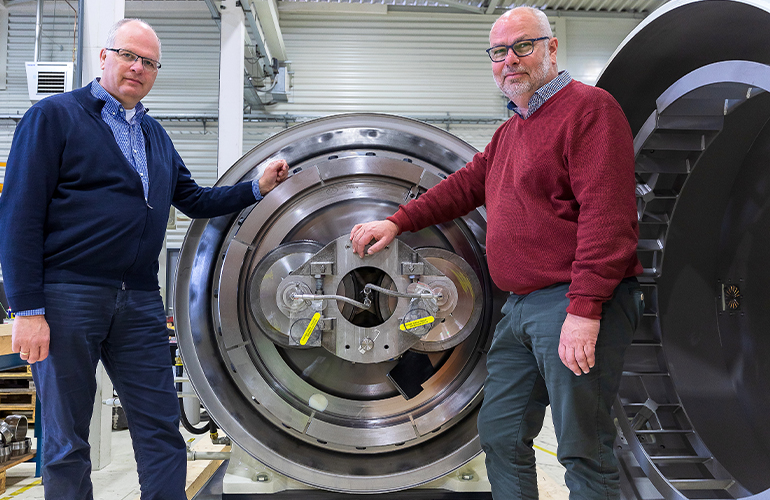

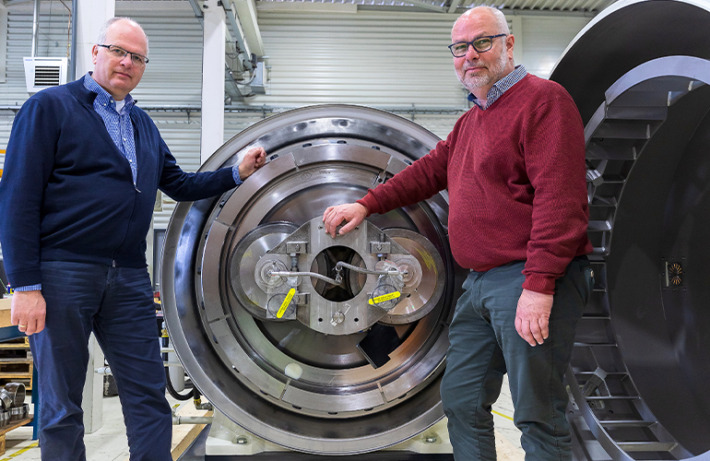

A revolutionary game-changer as Maarten Visser, General Manager of CPM EMEA/Americas explains to Bioenergy International during an exclusive preview in Zaandam, the Netherlands.

These are very exciting times for CPM, said Maarten Visser, previously CEO of CPM Europe and CPM’s Global Biomass Group, and recently promoted to General Manager of CPM EMEA/Americas, in anxious anticipation of the Twin Track launch.

A well-known and respected figure in the biomass pelleting world, Maarten Visser has been with the US-headed company (CPM Holdings Inc) in various positions throughout his entire professional career, and he is not the type of person to get overly excited about things.

However, after having seen what CPM is unleashing onto the marketplace, it is easy to understand the reason for this excitement.

The early 2000s is the only other time that I can recall feeling a similar vibe of optimism for biomass pelleting. Back then it was sawmills and project EPCs wanting to valorize wood residue streams for the energy sector that were behind the inquiries. The difference now is that all kinds of biomass are now on the discussion table and everyone is onboard including finance, he remarked.

Legacy of innovation

CPM or California Pellet Mill as it is formally called has a heritage that dates back to 1883. Over the decades, the company has earned a solid reputation and is held in high regard for its robust and reliable equipment across the board in sectors such as oilseeds processing, animal feed, and biomass.

Seen over time though, technological advances in ring die presses are seemingly few and incremental in nature.

In this context, “innovative” is perhaps not the first adjective that springs to mind if asked to describe CPM with five words.

Yet while the fundamentals of a ring die press remain unchanged, much-unseen development work has taken place, and not just at CPM, in terms of materials used, energy efficiency, die and roller configurations to mention a few.

CPM was in fact one of the first to pioneer wood pelleting back in the late 1980s, adapting its technology from the animal feed sector in which the company has a long and strong pedigree.

Since then, numerous other ring-die brands have entered the biomass space, yet CPM still commands a market share of approximately 25 – 30 percent of all ring die installations in biomass pellet plants.

Perhaps a few percentages more with the acquisition of Oklahoma-based pellet technology provider Bliss Industries Inc., in September 2021.

Those are your estimates. We know of course which plants we have equipment installed in but I’m afraid I have to refrain from commenting on things like market share, Maarten Visser said.

Innovation a driver

That there is much more to CPM than meets the eye is something that becomes apparent during a tour around the Zaandam office and workshop in Amsterdam, the Netherlands.

Innovation is very much a driving force but without the fuss – a quiet Kaizen “continuous improvement” approach.

That is until something big worth making a fuss about comes up. Such as when CPM launched its award-winning Oil Lubricated Roller (OLR) system.

Although the OLR-system has been out on the market since it was first showcased at Ligna in Germany five years ago, it still is picking up accolades, the most recent at Bio360 Expo in Nantes, France just days after the visit.

Centre of excellence

CPM Europe set up shop in the Netherlands already in the 1960s, and in the early 2000’s it became the corporate global centre of excellence for biomass.

– Our pilot pellet plant here in Zaandam has been going flat out with feasibility testing of diverse biomass feedstock from all around the world. Here we conduct both our own in-house research and third-party studies. We have a generic CPM testing facility in the US at our Crawfordsville location in Indiana. We’re looking to develop another biomass pilot and testing facility in Asia, to be closer to those markets, Maarten revealed.

Typically, third-party users of this feedstock feasibility service are looking to validate particular biomass or a combination of different biomass as a viable pellet feedstock.

This is to either diversify the feedstock base at an existing plant and adjust the pellet recipe accordingly, or as part of a larger new project study.

Generally speaking, we are seeing a movement toward pellets being produced from blended feedstock sources. We’ve had Asian clients have us determine the optimum pellet recipe using up to fourteen different wood species, Maarten said.

Commercial-scale pilot plant

A key point is that we use our smallest commercial pellet press rather than a lab press for the pilot. If we can produce pellets from the supplied material in the pilot plant, then we can scale the pellet press and associated ancillaries such as hammermills, conditioners, coolers, and conveyors accordingly to the desired output capacity, explained Maarten.

From a sales perspective, the pilot plant would in fact seem a strategic selling point for CPM.

Getting the discussion with a presumptive client into the pilot plant means that we can start talking from the same page. Not only can we contextually demonstrate what a CPM system is capable of doing but once the results are in, we’re able to move the discussion forward. As we know how to scale directly from the pilot, we can talk numbers in terms of equipment design capacities and so forth which saves both parties a lot of time and resources, he said.

Renewed interest in waste management

Apart from conventional biomass, CPM is making inroads in other allied sectors such as waste management and anaerobic digestion (AD) where it sees global growth opportunities.

The business and environmental logic of pelletizing non-recyclable waste is much the same as it is for biomass – produce a standardized, energy-dense, storable, and transportable product. CPM has been involved in this business for many years, recently there has been renewed interest in this sector, said Oskar Schaap, Sales and Marketing Director at CPM Europe, without elaborating on further details.

Smart Pelleting

As previously mentioned, CPM also conducts its own research in the pilot plant, testing not only different feedstock but also its own equipment.

Rapid advances in remote sensing technologies and sensors coupled with artificial intelligence (AI) and the Industrial Internet of Things (IIoT) open up a whole new universe of process technical operation, maintenance, and control opportunities.

We’re really only starting out on something we call Smart Pelleting. Things like pre-emptive maintenance, predictive analysis, real-time analysis, and remote operation are in front of us and are things that we can leverage from other companies within CPM Holdings, Maarten Visser said.

Enter Twin Track

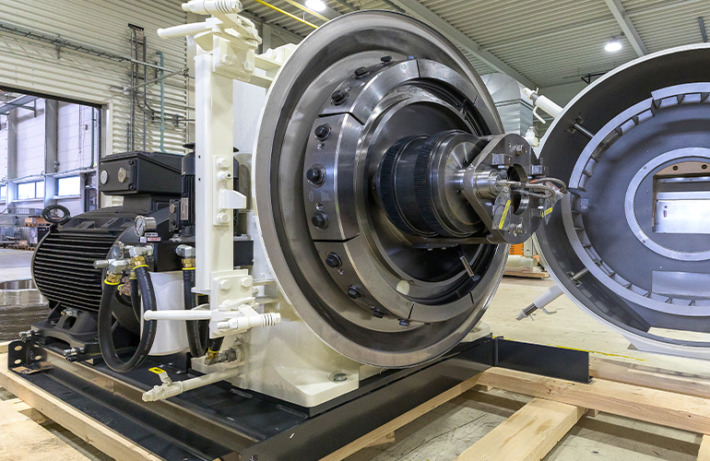

The pilot plant is also where CPM’s latest innovation worth making a lot of fuss over – the Twin Track – was tried, tested, and patented before entering commercial testing in CPM presses at a number of different pellet mills in Europe and Asia.

It represents the commercial culmination of a decade of research, with multiple goals of reducing energy demand, ensuring consistent pellet quality, and boosting mill capacity.

As the name suggests, it concerns the die and rollers and it is revolutionary in nature, pun intended. Like most good inventions, it is easy to understand.

Once you’ve seen it, a “why hasn’t anyone thought of that before” reaction is very likely, which is precisely why CPM has been exceedingly tight-lipped about its development.

We really wanted to keep this tight under wraps for as long as possible. In fact, you are the first outsider to be allowed to take photos even though we’d originally planned to launch the Twin Track in August/September last year. But with COVID-19 we decided to hold out and accumulate more operational runtime data from clients that have installed Twin Track in their plants, said Maarten.

How it works

In an effort to uphold a gentleman’s agreement, the following description of Twin Track is, on purpose, “accurately vague”.

Basically, what CPM has achieved is a series of proprietary die and twin roller design embodiments and configurations.

What’s special is that each design configuration ensures that each part of the working surface of the die, is passed over only once per cycle by the working surface of a roller.

By comparison, with conventional die-roller design and configurations with two or three rollers, the working surface of the die can be passed over by the working surface of a roller two or three times per cycle.

In other words, CPM has succeeded in removing the die-roller working surface overlap.

This translates directly into energy savings, up to 10 percent less when compared to a conventional die-roller set-up, to produce the same result in the same timeframe with the same turnover per unit time and produce pellets of the same quality, said Maarten.

Less power consumed means less cost, and less heat generated which in turn, extends the service life of wear-parts reducing operational costs further.

Lowering energy consumption in the process also helps producers to improve the overall carbon footprint of their production.

Increase productivity

With Twin Track we can also increase the productivity of a press by increasing the width of the die’s working surface area but without changing other dimensions of the machine. This means that it is possible to increase production capacity by around 10 percent, said Maarten Visser, adding that one needs to ensure that the infeed and post-press ancillaries can manage the increase.

According to CPM, the Twin Track provides a working surface area with up to 43 percent more holes in the die compared to a comparable sized conventional die. Thus, for every cycle, the Twin Track creates a larger product layer, resulting in a greater volume of pellets.

Furthermore, CPM’s research team has validated that a higher hole count in the die also facilitates longer ‘baking time’ in the die itself, making use of natural binding properties, including added binders, while maintaining pellet consistency.

From the extensive testing in real-world mill operations, the higher die hole count in Twin Track has been found to stabilize mill running conditions. This is attributed to the higher pellet retention times which help to dampen fluctuations.

Twin Track can either be supplied in new CPM machines or be retrofitted to a range of CPM machines, in as little as four hours.

To achieve maximum results with the Twin Track, most installations will require the OLR-system, Maarten added.

To recap, the OLR-system uses closed-loop oil circulation to ensure continuous lubrication of the rollers. An oil flow to each individual roller enables continuous monitoring and control of the roller bearing temperatures.

In addition, the closed system prevents lubricant from entering the rollers or contaminating the pellets whereas the filtered oil flow removes potential wear particles from the bearings.

This significantly reduces the operating costs by extending the lifetime of the bearing and enables the re-usage of the lubricant.

An after-market game-changer?

The Twin Track provides pellet plants with an attractive set of options within the same pellet island footprint – increase production capacity, reduce operating costs or do both.

Our goal was to revolutionize the pellet mill from the inside, and Twin Track technology does exactly that. Mill operators can now leverage greater energy savings, and greater capacity while lowering maintenance costs. It really is a win-win for the pelleting industry, remarked Oskar Schaap.

CPM clients aside, the real game-changer, and reason for being so “accurately vague”, is perhaps to be found in the after-sales market. Dies- and rollers are wear- parts, and for original equipment manufacturers (OEMs) like CPM, they are an important part of the overall business model.

At the same time, there are third-party die and roller players on the market while savvy pellet plant operators are not afraid to mix and match brands that they find work the best for their operations.

The Twin Track is of course designed for CPM presses and its benefits are verified on CPM equipment, ended Maarten Visser on a diplomatic note.

After all that was seen and said in Zaandam, it is only time that will tell how much of a stir CPM’s innovative Twin Track is to become.

In the meantime, one can only concur with Maarten’s opening remarks – very exciting times indeed for CPM.