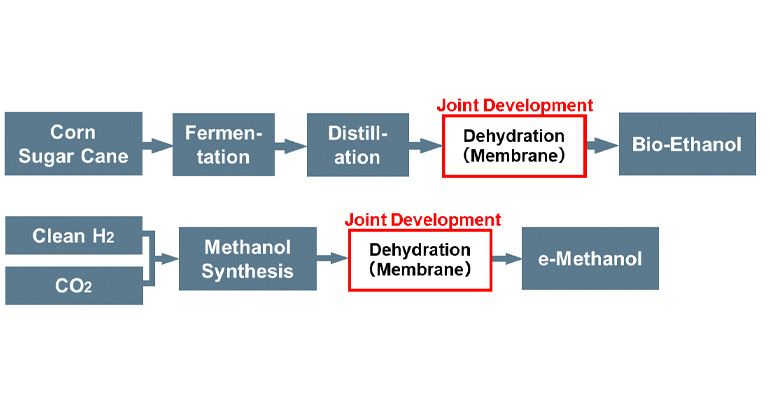

Japan-headed NGK Insulators Ltd (NGK) and compatriot Mitsubishi Heavy Industries Ltd (MHI) have announced that they will jointly develop two membrane dehydration systems to realize low cost and optimize the efficiency of manufacturing processes for bioethanol and e-Methanol to meet expected demand growth for clean fuels and raw materials.

Bioethanol is a clean fuel derived from plants, primarily corn and sugarcane, and is widely used as automotive fuel in the United States (US) and Brazil. It is also expected to contribute to the growth of sustainable aviation fuel (SAF) as one of its main raw materials.

e-Methanol is gaining attention as a next-generation clean fuel, primarily for marine fuel, and is expected to grow as a market globally.

Develop membrane dehydration systems

In this project, MHI and NGK will begin developing two types of membrane dehydration systems, one for bioethanol and e-Methanol, respectively.

The membrane separation system developed for bioethanol will replace the conventional dehydration process, which consumes the most energy in the bioethanol manufacturing process.

This replacement is expected to achieve a significant reduction in the energy required to produce bioethanol.

The second system will replace the dehydration process in the production of e-Methanol, which utilizes hydrogen and carbon dioxide (CO2) as raw materials.

By using a membrane separation system instead, the companies expect to significantly reduce energy consumption used in the manufacture of e-Methanol, which is capturing attention as a next-generation clean fuel.

To this project, MHI will contribute its significant global expertise in delivering methanol plants and other chemical plants, in addition to its technologies for handling methanol and various other chemicals.

Sub-nano ceramic membrane tech

NGK will contribute its deep knowledge of sub-nano ceramic membrane technology and unique film deposition technology developed in chemical processes and water purification.

NGK has developed the world’s largest ceramic membranes, known for their exceptional separation accuracy and durability.

In the context of forecasted demand growth for bioethanol and e-Methanol as clean, raw materials and fuels, MHI and NGK will jointly drive forward the development of these systems to achieve real-world deployment and a stable supply system.