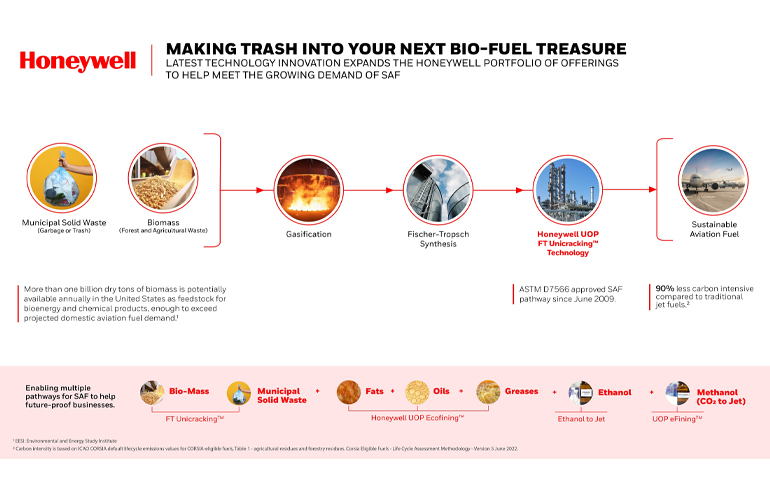

In the United States (US), global industrial technologies, processes, and performance materials major Honeywell International Inc (Honeywell), has announced its new "Unicracking" hydrocracking technology can be used to produce sustainable aviation fuel (SAF) from biomass, helping to make sustainable aviation fuel (SAF) that is 90 percent less carbon intensive than traditional fossil-based jet fuels.

By utilizing proprietary SAF selective Honeywell UOP hydrocracking and hydro-isomerization catalysts, and a Honeywell patent-pending process configuration, the new technology produces 3-5 percent more SAF enabling a cost reduction of up to 20 percent, and reduces by-product waste streams as compared to other commonly used hydroprocessing technologies and configurations.

Honeywell’s Fischer-Tropsch (FT) “Unicracking” technology takes liquids and waxes from processed biomass – including leftovers from crops, wood waste, or food scraps – and can be used to produce SAF that complies with the strict standards of the aviation industry and with a lower environmental impact.

This innovation demonstrates Honeywell’s alignment of its portfolio with three compelling megatrends, including the energy transition.

As demand for SAF continues to grow, the aviation industry is challenged by limited supplies of traditional SAF feedstocks such as vegetable oils, animal fats, and waste oils. When combined with the existing Fischer-Tropsch process, our new technology will expand the feedstock options available in the industry to sources that are more plentiful, ultimately helping improve our customers’ ability to produce SAF, said Ken West, President and CEO of Honeywell Energy and Sustainability Solutions.

DG Fuels selects Honeywell FT Unicracking

Recently, DG Fuels selected Honeywell’s FT Unicracking technology for its biofuels manufacturing facility in Louisiana – the largest in the world for making SAF from the FT process – that will produce 13,000 barrels of SAF per day when it begins operations in 2028.

Using Honeywell’s advanced technology, DG Fuels will supply enough fuel for more than 30,000 transatlantic flights every year, contributing significantly to reducing the carbon emissions of global air travel. This is a big leap forward in supporting the airline industry’s goal of reaching net zero carbon emissions from international aviation by 2050, said Michael Darcy, CEO of DG Fuels.

Honeywell helped pioneer SAF production with its “Ecofining” process, which has been used to produce the fuel commercially since 2016.

The company now offers solutions across a range of feedstocks to meet the rapidly growing demand for renewable fuels, including SAF.

In addition to Honeywell Unicracking and Ecofining, Honeywell’s renewable fuels portfolio includes ethanol-to-jet (EtJ) technology and eFining, which converts green hydrogen and carbon dioxide (CO2).