Australia-headed technology company Hazer Group Ltd (Hazer) has announced that it has signed a non-binding Memorandum of Understanding (MoU) with POSCO Steel (POSCO) to prepare a project pathway for the integration of Hazer’s hydrogen technology into POSCO’s low-carbon steel.

Based in Pohang South Korea, POSCO is one of the world’s largest steel makers and has announced its plan to achieve carbon neutrality by 2050. With POSCO Holdings in the lead, POSCO Group seeks “balanced growth” across seven core businesses: steel, rechargeable battery materials, lithium/nickel, hydrogen, energy, construction/infrastructure, and agri-bio.

These businesses propel POSCO Group’s evolution into a leading provider of eco-friendly future materials, net-zero steelmaker, future transportation architect, green energy pioneer, innovator of future housing, and global food supplier.

Collaborate to integrate processes

Steelmaking is a carbon-intensive industry, responsible for over 8 percent of global carbon emissions.

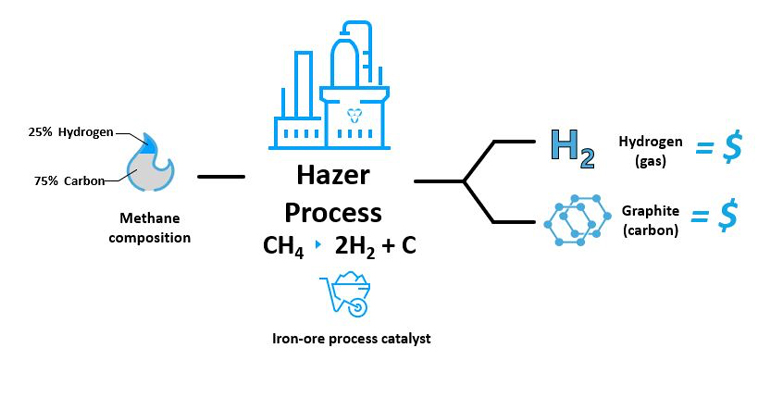

Hazer Group’s proprietary methane pyrolysis technology is uniquely positioned to support the decarbonization of steel manufacturing using affordable, clean hydrogen and Hazer Graphite production, using iron ore as a process catalyst.

The MoU has an initial term of two years. During this time, the parties have agreed to work collaboratively to develop plans to integrate Hazer’s hydrogen technology into POSCO’s low-carbon steel manufacturing process and project development agreements.

Each party is responsible for its own cost to meet the objectives under this MoU. Parties are permitted to develop similar projects independently.

POSCO and Hazer Group will also assess the application of Hazer’s low-emissions graphite product in various parts of the steel-making process, and a market investigation into the applications of Hazer graphite outside of steel.

At POSCO we are incredibly focused on the reduction of emissions from the steel-making process and have committed to reducing worksite emissions by 10 percent by 2030, 50 percent by 2040, and being 100 percent carbon neutral by 2050. We believe Hazer’s unique technology offers important benefits that enable us to achieve our Net Zero vision as set out in our 2050 Carbon Neutrality Roadmap, said Dr Seong-yeon Kim SVP and Head of Technical Research Lab at POSCO.

This MoU follows an extensive period of due diligence conducted by POSCO on Hazer Group, its proprietary technology to produce clean hydrogen and graphite, and initial technical discussions around the technology integration.

I am delighted to begin this significant collaboration project with POSCO, one of the world’s largest and most competitive steelmakers, demonstrating how large and varied the commercial opportunities are for Hazer and its technology. We identified the steelmaking industry as one of our key strategic and commercial targets for the Hazer Process given it is notoriously hard to abate the sector. It is a great privilege and a fantastic achievement to be working alongside such a large company that is dedicated to carbon neutrality. This MoU will enable the next phase of our scale-up strategy into this key market with a significant company known for its sustainability focus and innovation. We look forward to our future in decarbonizing the steel-making industry and achieving commercial success with POSCO, said Glenn Corrie, CEO, and Managing Director at Hazer Group.

Hazer continues to have ongoing discussions on the application of both hydrogen and graphite in the blast furnace and Direct Reduced Iron (DRI) / Electric Arc Furnace (EAF) steel-making processes with leading steel makers worldwide.