Say Wels and many would associate the Upper Austrian city with its almost legendary annual World Sustainable Energy Days. That Wels is also home to Sturmberger Pelletsproduktions GmbH, a pocket-sized state-of-the-art pellet plant, is perhaps not as widely known. Yet it is almost legendary in its own right.

Please reload the page

Do you want to read the whole article?

- Six editions per year

- Full access to all digital content

- The E-magazine Bioenergy international

- And more ...

Located on the outer fringe of Wels, on a site next door to Energia AG’s waste incineration plant, Sturmberger Pelletsproduktions is the pellet production facility of family-held Sturmberger Group.

Founded by Franz Sturmberger as a one-man chipping operation in Wartberg an der Krems just 25 years ago, the Group has grown into a sizeable operator in the biomass fuel space.

With a total of 70 staff, the Sturmberger Group provides truck-mounted chipping services, production, sales, and deliveries of woodchips, mulch, and pellets.

Pocket-sized is in all sincerity meant as a compliment. The entire 65 000 tonnes per annum (nameplate) facility, including the log cabin style office, feedstock- and pellet storage, all fit on a one-hectare (ha).

That’s 10 000 sq.m with plenty of space to spare. Indeed, the plan is for an additional 30 000 tonnes annual capacity on the same site.

This means that the productivity footprint will increase from 6 tonnes of pellets per square meter per year to 9 tonnes per sq.m/year.

An impressive and important metric, especially seeing as the term environmental impact has grown to encompass pretty much everything.

There are three main cost drivers behind the design and location of our pellet plant. The cost of land, the cost of energy, and the cost of labour, explained Bernhard Sturmberger, CEO of Sturmberger Pelletsproduktions during a visit to the plant.

An atypical facility

On arrival, one thing becomes apparent. The standalone pellet plant is not integrated with a sawmill nor is there any wood processing facility in the vicinity, yet it is fully stocked with sawdust.

For us, it is cheaper to truck in all our feedstock from about a 100 km radius. In addition, we can aggregate material at the Group’s site in Wartberg. As you can see, the feedstock is not an issue, Bernhard explained.

The incoming trucks are weighed both on arrival and exit. The sawdust is priced using an average coefficient determined by moisture content, weight, and volume.

We don’t sample every truckload, just random sampling. Most of our feedstock is from sawmills many of whom we have a long relationship, so there is an element of trust. Seen over time it works well, explained Tamas Engler, Production Manager.

Sensing my concern over such large stockpiles of sawdust, he added that the feedstock turnover is high, the piles are disturbed almost daily, and nothing lies around long enough to cause self-heating issues.

Utilize residual heat

As we round the sawdust pile, which I’m told is enough for about a fortnight of 24/7 pellet production, and face the dryer, a second feature becomes apparent.

Or rather a feature missing – there is no flue stack or boiler in the “boiler house”. Instead, inside there is a large heat exchanger.

As Bernhard said, energy is expensive. We save both CAPEX in terms of additional land and a boiler plant, and OPEX in terms of having to buy in fuel, and operate a boiler. A 300-metre underground pipe to the incineration plant and this building for the heat exchanger is all that’s needed. OPEX is now reduced to a utility bill based on MWh heat used. And there is plenty of heat available for our expansion needs, Tamas Engler said.

As a “by the way”, Sturmberger Pelletsproduktions was the very first industrial user of residual heat from the waste-to-energy plant.

Since then, a whole new district heat infrastructure has been developed to service nearby businesses and new residential expansions.

Bespoke PELLET.TOWER’s

A distinguishing feature, and the main reason behind Sturmberger Pelletsproduktions having such a compact plant footprint, is that, unlike a conventional plant set-up, the pellet lines are vertical.

Even though they are vertical they are still compact and not skyscrapers, which means they are within various building code regulations. That simplifies permitting applications, Tamas said.

The plant was designed and built by Austrian company Teccon Engineering GmbH, part of the Teccon Group that specializes in the design and supply of steelworks, machinery, and industrial plants.

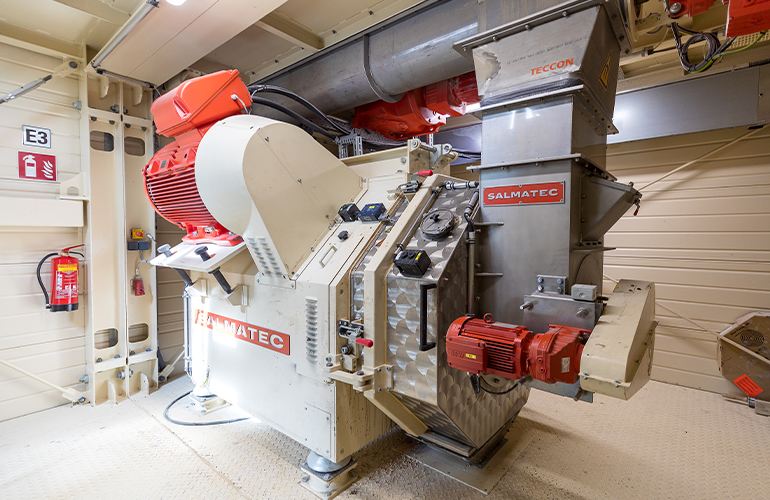

Teccon has a proprietary tried and tested concept known as the “PELLET.TOWER”, a modular system in which all the functions of the pelleting island – feedstock grinding, moisture control, conveying, pressing, cooling, and pellet screening are integrated into the PELLET.TOWER and operated automatically.

According to Teccon, by using gravity, and pneumatic conveyance, conveyance distances, and costs are kept to a minimum. State-of-the-art fire and explosion protection are built into the design while an online weighing system records production volume in real-time.

For service and maintenance, a central vacuum system enables easy cleaning on the different levels, a service door and protruding gantry crane joist on level three means that heavy items such as dies, rollers, grease drums, and starch sacks, can be hoisted into the press room.

Furthermore, as the Teccon units are modular in nature, it means relatively uncomplicated transport to a construction site and short assembly time when on-site, all of which have positive impacts on a project’s financials.

Process description

Whilst the incoming feedstock is almost exclusively from a single species – Norway spruce (Picea abies) and some European silver fir (Abies alba) – it consists of both raw- and dry sawdust, and shavings.

Thus, it has varying moisture content and so needs to be dried down to a uniform moisture content of about 10 percent before entering the PELLET.TOWERs.

From the various stockpiles, the material is loaded by a wheeled loader into a receiving bunker for the belt dryer. Prior to entering the dryer, the material is screened to remove oversized material and any contaminants such as stones and passes under a magnet to remove any ferrous metals.

The material enters Teccon’s BDT 24, a low-temperature belt dryer, where the incoming material is evenly spread across the width of an air-permeable fabric belt using a set of screw conveyors.

The dryer has a nominal water evaporation rate of 6 tonnes per hour. It is indirectly heated using residual heat from the waste-to-energy plant via a heat exchanger.

This means that the dryer circuit is totally autonomous from the heat source. Thus, the dryer can be ramped up, turned down, or turned off as the downstream pellet production process dictates. Material thickness, air suction- and exhaust fan speeds, and belt speed are all controllable parameters.

Right now, it is actually running at about 75 percent capacity, as we have stopped production in line one to carry out a scheduled die switch in the press, said Tamas.

On exiting the dryer, the material is conveyed to the intermediary storage silo located behind the two pellet towers.

Material is taken out from the bottom of the storage silo on a first in first out principle. Like a fuel level indicator in your car, the silo has a level sensor indicating how much material is inside, Tamas explained.

Once a certain level in the silo is reached, the dryer capacity is automatically turned down.

From the silo, the material is fed into an intake bin on level two that feeds a Tietjen hammermill located on level one. From here the sized material is screened and pneumatically conveyed into a conditioning container on level four.

Oversize from the screening is conveyed back to the intake bin on level two by a vertical screw conveyor. From the conditioning container, the material is metered into a Salmatec press located on level three to produce the 6 mm pellets. A starch binder is also used in production.

From the press, the pellets pass a Teccon counterflow fluidized-bed cooler on level two, before screening in a Teccon tumbler screener to remove fines on level one. The fines are recirculated back to the intake bin on level two.

The cooled and screened pellets are then conveyed to one of the two 3 500 tonne capacity storage silos.

From these storage silos, the pellets are either conveyed to one of the two bulk storage silos from which bulk delivery trucks load, or the bagging line silo.

All production is 6 mm and ENplus A1 quality. The majority is supplied to domestic clients by a bulk delivery truck. We have two bulk filling stations and operate our own fleet of branded trucks, Tamas Engler said.

Automatic bagging line for export

While some of the production is bagged in 15 kg and 10 kg bags for the domestic stove market, approximately 12 percent or 7 000 tonnes of annual production is bagged in 15 kg bags for export to Italy.

The entire six tonnes per hour bagging and palletizer line, supplied by Fisker Skanderborg, is automatic.

There is no need for a dedicated operator. There are only four basic functions to monitor; replace the bag plastic roll, replace the shrink-wrap roll, load a stack of empty pallets, and remove the finished pallet of pellets to storage, said Tamas.

The covered storage for bagged stock can hold around 1 300 tonnes. Interestingly, the bagged pellets for Italy, which are exactly the same as those delivered by bulk or bag in Austria, are branded differently.

It’s a marketing thing. I’m not Italian but I guess Steirer Sticks sounds much catchier than Sturmberger Pellets, remarked Tamas.

Expansion plans

The entire facility is operated from a control room in a centrally located building that houses the bagging line to the rear of it and bulk truck filling stations to one side.

The building also houses the lab room for feedstock and pellet control sampling, staff changing room, and canteen. The pelleting plant operates 24/7 while feedstock and bulk truck deliveries are restricted to more conventional working hours.

Sturmberger Pelletsproduktions has been conceived with efficiency and future expansion in mind. Each pellet tower line has a nominal production capacity of approximately 40 000 tonnes per annum.

Completed in 2014, the first line began production in 2015, and in early-2021, line two came online doubling the nominal output capacity. Space for a third tower line was already on the table from the outset. Each tower line requires, in principle, one operator per shift to run.

We plan to add a third line to bring the plant up to the overall original design capacity for the site. That has been the vision from the start, it has just been a question of if and when we should make the necessary incremental investments, said Bernhard Sturmberger.

A permitting application has been sent to the local authorities to add additional dryer capacity as this will be needed for a third line.

The new dryer is planned to be located on top of the existing one.

The overall footprint will remain the same. It will mean having to raise the noise barriers on the dryer but that really is a minor issue, he said.

Looking ahead further into the future, the grand plan for Sturmberger Pelletsproduktions is then to mirror the entire 90 000 tonnes per annum plant on a new 10 000 sq.m site adjacent to the existing one.

That is what we hope to achieve. We believe that is both possible and feasible to operate a 180 000-tonne pellet plant on a two-hectare site here in Wels. The residential pellet market is developing well in the region, there is ample feedstock available, and we have a highly efficient low-impact production concept, ended Bernhard Sturmberger.